- Quick set-up and dismantling: The structural design of the containers allows them to be quickly unfolded and folded, saving set-up time and labor costs.

- Reusable: These houses can be built and disassembled repeatedly, which is convenient for use in different places, saving resources and costs.

- Mobility: The container itself is designed to transport goods, and the portable folding container house is convenient for relocation and transportation between different locations.

- Structural stability: The structure of the container has been designed and tested by engineering, and has good stability and carrying capacity.

- Windproof and waterproof: These houses are usually sealed in design, which can be effectively windproof and waterproof, providing a comfortable and safe indoor environment.

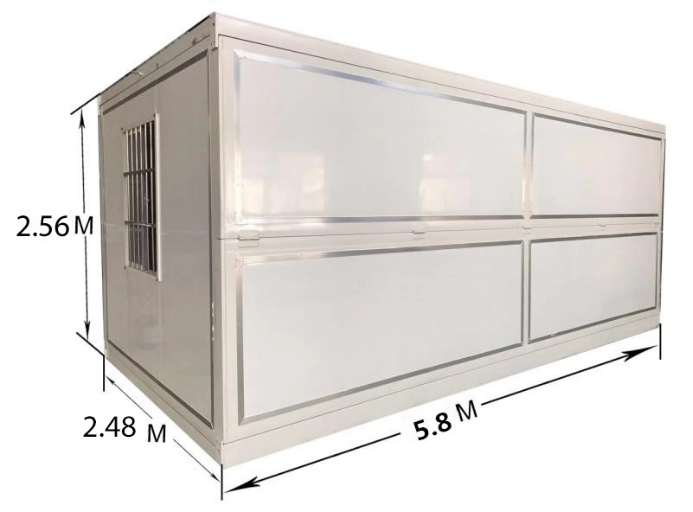

PRODUCT SPECIFICATION:

| iguration – Standard Folding Container | ||

| Specification | external dimension (mm) | 5800*2480*2560 |

| Internal dimension (mm) | ||

| Package dimension (mm) | 5800*2480*410 | |

| Weight | ≈1300KG | |

| Index | Structural Design Service Life | 10 years |

| ground live load | 200kg/㎡ | |

| roof live load | 100kg/㎡ | |

| wind load | Grade 8 | |

| Seismic Fortification Intensity | Grade 10 | |

| Main structure | Top frame | Main beam Q235B rectangular square tube |

| Secondary beam Q235B rectangular square tube | ||

| Secondary beam Q235B rectangular square tube | ||

| Bottom frame | Main beam Q235B rectangular square tube | |

| Main beam Q235B rectangular square tube | ||

| Secondary beam Q235B rectangular square tube | ||

| side | Main beam Q235B galvanized P-type pipe | |

| front and back | Main beam Q235B galvanized P-type pipe | |

| corner | Q235B thickness 8mm | |

| folding hinge | Galvanized hinge, high strength | |

| Roof | Integral frame protective coating | Electrostatic spray/straight white plastic powder |

| external roof | Galvanized sheet | |

| interior ceiling | Color steel veneer V831,0.37mm | |

| Wall panel | Insulation glass wool | glass wool roll 50mm |

| side wall | 0.3/0.3 75mm Thick glass wool composite board | |

| Front and rear wall panels | 0.3/0.3 75mm Thick glass wool composite board | |

| Floor | cement mix floor 15mm | |

| Electrical System | Electrical wiring is installed in strict accordance with moisture-proof specifications, and all electrical products meet CE certification. Connect the circuit according to the circuit engineering specification, indoor: 4² national standard annealed copper wire, 1 32A circuit breaker, 1 three-hole air-conditioning socket, 2.5² socket incoming line, 1 five-hole single-open socket, 1 five-hole socket, 1 LED light | |

| door | High quality anti-theft door (warm white) size: 860mm*1990mm | |

| window | 920*920 single glass sliding window plastic steel window with guardrail screen window, glass thickness 4mm | |

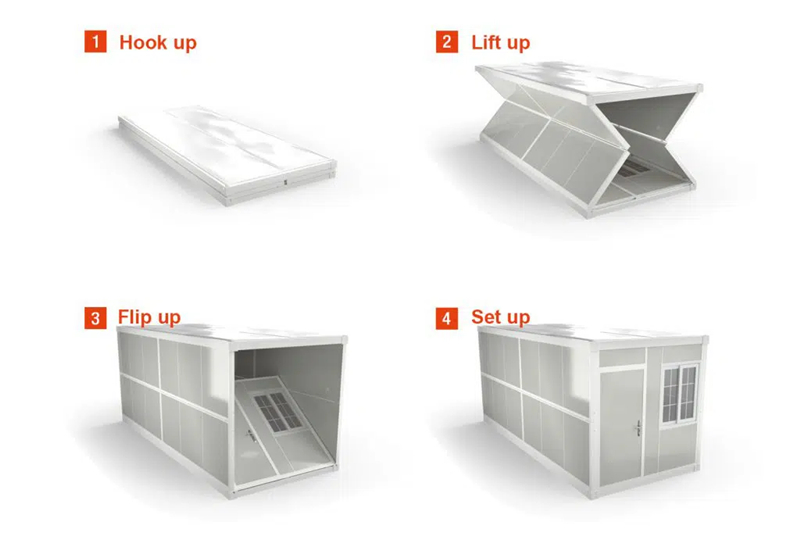

INSTALLATION METHOD:

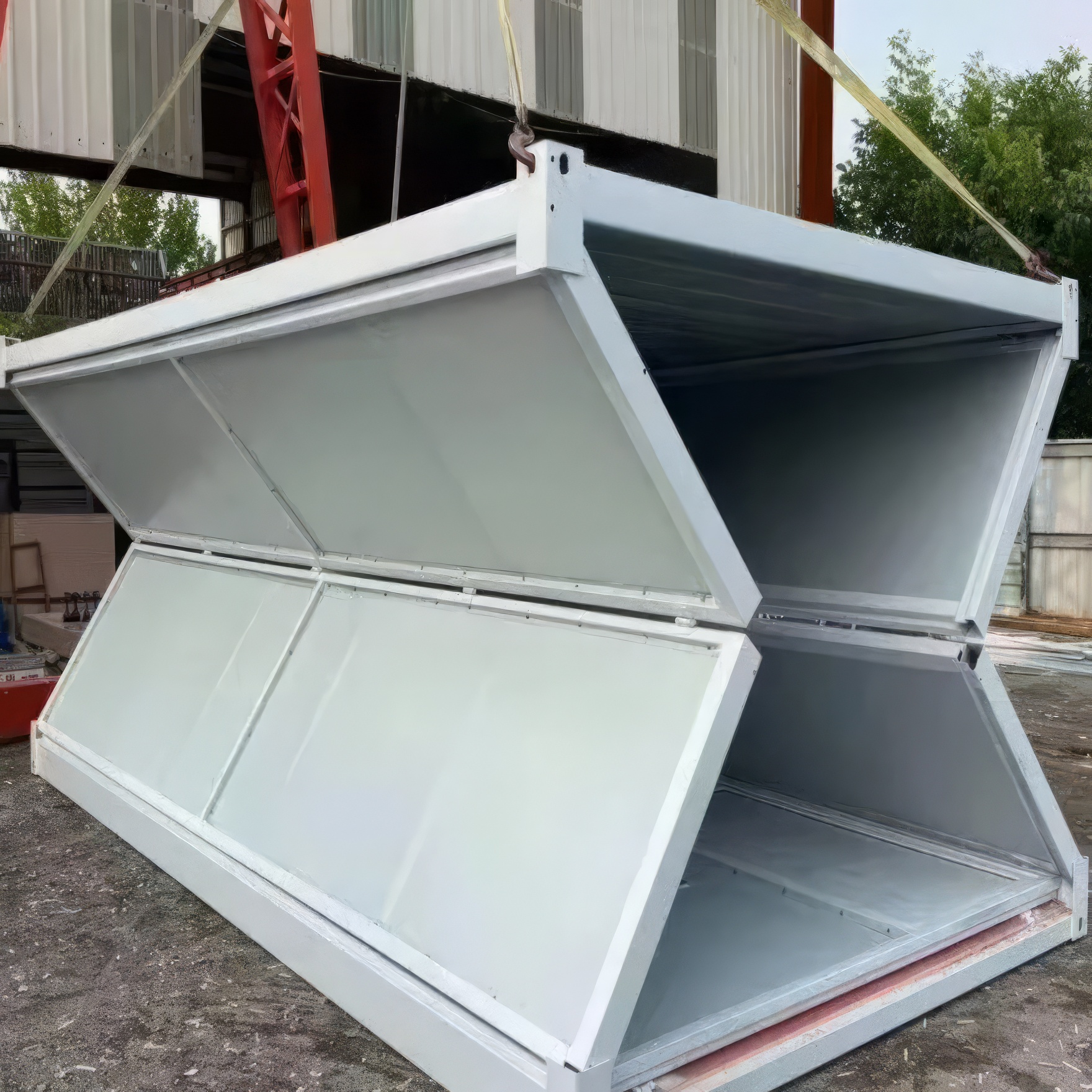

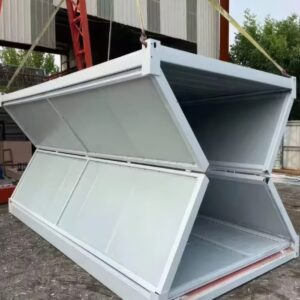

The production and assembly of all the components of the folding container house are prefabricated at the factory. You can install the Folding House on the job site in just four steps.

- Use the crane to live its roof. Lift its roof slowly until the house is unfolded and stop the crane there.

- Expand the front and back walls of the container. Push the front and back from inside, and make it stand in the correct place.

- Use the bolts to fix the whole structure. There will be premade bolt holes on the columns, and we will provide enough bolts for you to fix them.

- Install the door lock. To prevent the door lock from damaging the ceiling during the folding process, we will not install the door lock in advance. If you need to move the house to another place and need to fold it, please remember to take down the door lock in advance also.

Reviews

There are no reviews yet.